vickers hardness test formula derivation|vickers hardness conversion calculator : broker These approximate relationships between hardness and tensile strength do not . Resultado da 984k 100% 45sec - 360p. Gang bang com a novinha no meio do mata ( videos https://rabudas.tv) 3.9M 98% 22min - 360p. Cameracaseira .

{plog:ftitle_list}

WEB23 de fev. de 2024 · Gambling can be addictive, please play responsibly. U.S. Real Money Casinos Quick Facts. ⭐ Top casino operator. DraftKings Casino. 💰 Biggest welcome bonus. Caesars Palace - Deposit match up .

The Vickers Hardness number (HV) is the ratio of the load applied to the surface area of the indention. This is done with the following calculator and formula. HV = P / ( 0.5393 d 2 )

Brinell Hardness Testing. Engineering Metals and Materials Table of Contents. .Rockwell Hardness Testing Review. Engineering Metals and Materials Table .

Hardness Testing Review. Engineering Metals and Materials Table of Contents. .

These approximate relationships between hardness and tensile strength do not . The Vickers hardness (HV) is calculated using the following Vickers hardness formula: where d is the average of the two diagonals of the imprint and F is the applied load. .It was decided that the indenter shape should be capable of producing geometrically similar impressions, irrespective of size; the impression should have well-defined points of measurement; and the indenter should have high resistance to self-deformation. A diamond in the form of a square-based pyramid satisfied these conditions. It had been established that the ideal size of a Brinell impression .The Vickers hardness is the quotient obtained by dividing the kgf load by the square mm area of indentation. F = Load in kgf. d = Arithmetic mean of the two diagonals, d1 and d2 in mm. HV = Vickers hardness.

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers .Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area .

The hardness number can be calculated by the load over the surface area of the indentation. Implementation. The angle between the two faces of diamond indenter used in Vickers hardness test is 136° and the faces makes an angle .

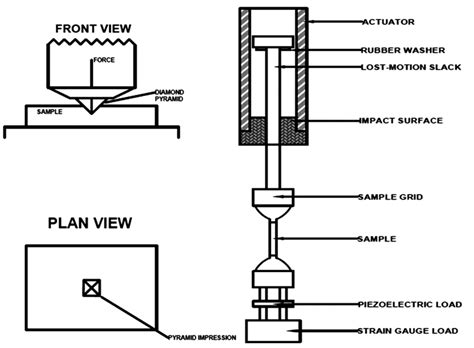

vickers hardness testing machine diagram

vickers hardness test procedure pdf

Artificial Light Color Fastness Tester fabrication

Vickers hardness test is also known as the diamond pyramid hardness test which employs a diamond pyramid indenter and variable loads ranging from 1 to 120 kg. The Vickers hardness .The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low .The principle of the Vickers hardness test is based upon micro-indentation. The test method is usually performed with a hardened steel ball pressed into a flat surface of the material being .

A bench-based Vickers microhardness test machine (Figure 9.15) is similar in principle to a standard Vickers hardness tester, except much lower loads are used (between 1 and 1000 g) and, therefore, much smaller indents are formed into the specific region of interest. A similar principle is used in the Knoop hardness test, except that an .The Vickers hardness test was developed by RL. Smith and Sandland in 1921 at Vickers Ltd as an alternative to brinell hardness test method to measure the hardness of the material. The Vickers hardness test follows the brinell .The Vickers method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6507, ASTM E92, ASTM E384).

https://engineers.academy/This video outlines how a Brinell hardness test is conducted, as well as explaining how to calculate a value for the Brinell hardne.apparent hardness when testing curved surfaces to the hardness of a plane surface by using a correction factor. In this test, we introduce an example of correction using a Shimadzu HMV-G series micro Vickers hardness tester as an example of a Vickers hardness test of curved surfaces. C. Oya Hardness Correction Factors in Tests of

The Vickers hardness test was developed as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests, since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of .

The Knoop hardness test uses a rhombohedral-shaped diamond indenter. The long diagonal is seven times (7.114 actually) as long as the short diagonal. With the indenter shape, elastic recovery can be held to a minimum. The Knoop hardness test is conducted in the same manor, and the the same tester as the Vickers hardness test. However, only the . For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .Several methods have been developed for hardness testing. Those most often used are Brinell, Rockwell, Vickers, Tukon, Sclerscope, and the files test. . The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used .

The Vickers hardness (HV) results from the quotient of the applied test force (F in newtons N) and the surface area of the residual indent on the specimen (see formula below). To calculate the surface area of the residual pyramidal indentation, the average of the two diagonals d1 and d2 (in mm) is used, because the base area of Vickers indents is frequently not exactly square. The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.E 140 Hardness Conversion Tables for Metals (Relationship Among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Rockwell Superficial Hardness, Knoop Hard-ness, and Scleroscope Hardness)3 E 384 Test Method for Microindentation Hardness of Ma-terials3 3. Terminology 3.1 calibration—determination of the values of the signifi-

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that takes into account the applied load and the surface area of the indentation. .Learn more about hardness testing basics here. The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an .

INNOVATEST explains the Vickers Test MethodThe Vickers hardness test is similar to the Brinell test. However, it uses a four-sided inverted diamond pyramid with an apex angle of 136°. The Vickers hardness number (HV) is the ratio of the impressed load to the square indented area. The Vickers hardness test is of particular value for hard, thin materials where hardness at a spot is required.

Mechanical Properties (Hardness Test)Prof. Ratna Kumar Annabattula Department of Mechanical Engineering IIT MadrasHardness Test

The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the material being tested. The diameter of the indentation is then measured, and the result indicates the hardness of the sample. There is a formula that can help you calculate .As shown in Fig. 3.12, the Vickers hardness curve remains practically straight at all hardness values, whereas at hardness above 300 kg/mm 2 the Brinell hardness curve starts bending to result in a lower value and it diverges remarkably causing an unacceptable hardness value above 600 Brinell, where the Vickers test is considered to be a .ISO 6507에 Vickers Hardness Test의 진행방법 또는 장비를 교정하는 방법등이 나와 있으며 ASTM 코드는 E92에 해당 테스트에 대한 내용이 들어가 있다. 비커스 경도 시험을 하는 방법은 브리넬 경도 시험과 거의 동일하다. 다른점이 있다면 압자(Indenter)의 재료이다.

The test was devised in 1939 by F. Knoop and colleagues at the National Bureau of Standards in the United States. By using lower . By using lower indentation pressures than the Vickers hardness test, . is derived from the following formula: HK = 14.229(F/D 2), with F being the applied load (measured in kilograms-force) . The formula for fracture toughness in units . . define Vickers hardness (HV) as the load divided by the contact area of the four faces of the . Vickers IF test are considered in turn.The Vickers Hardness Number (VHN) for this material is approximately 13905. FAQs. What is the Vickers Hardness Number (VHN)? The Vickers Hardness Number quantifies the hardness of a material based on the size of the indentation created by a specific force. How is the Vickers hardness test performed?The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .

Solar Radiation Simulation Tester–(wind cooling) fabrication

vickers hardness test diagram

14 de fev. de 2024 · Robocop: Cash Collect is a casino slot from Playtech based on the American science fiction movie Robocop from 1982. Starring Peter Weller, the movie quickly became a cult classic containing dark humor and a satirical vibe with lines such as “Dead or alive, you’re coming with me!”. Robocop: Cash Collect game offers a trip back .

vickers hardness test formula derivation|vickers hardness conversion calculator